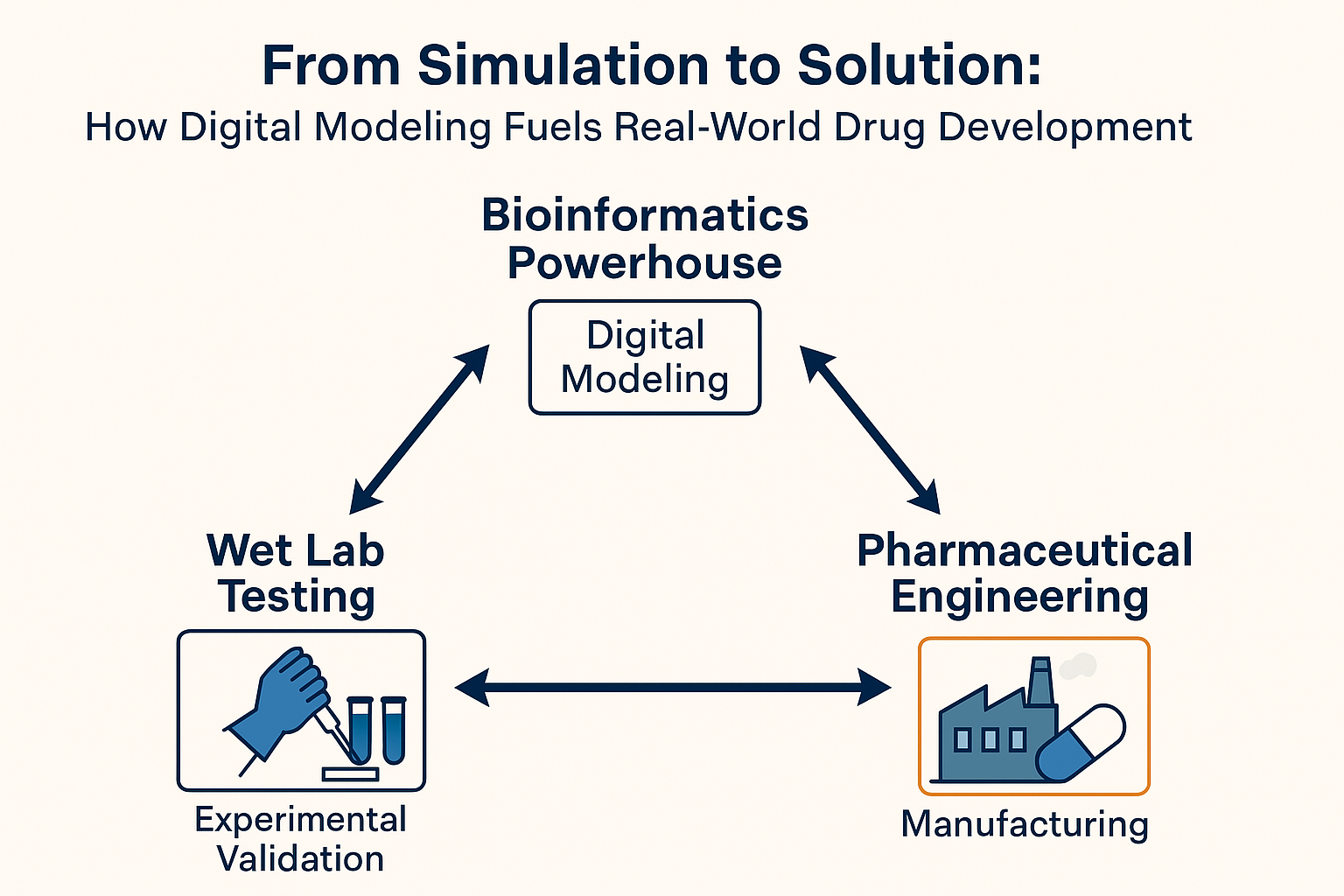

In the current pharmaceutical

environment, the path to innovative therapies starts on a screen rather than on

a production line or petri dish. Digital intelligence is driving medication

research to become more precise, linked, and agile. In silico modeling is at

the center of this change, a digital powerhouse that acts as the engine and

compass for industrial-scale manufacturing and experimental research. These

three domains—pharmaceutical engineering, wet lab testing, and prediction

technologies—create a dynamic feedback loop. Each domain feeds into the others

in an ongoing triangle of innovation.

Digital Modeling: The

Bioinformatics Powerhouse

Bioinformaticians use extensive computational infrastructure to model the behavior of molecular structures before a single molecule is created or tested. Digital modeling makes use of high-performance computers, bioinformatics, and artificial intelligence to:

1. Check for possible biological activity in billions of chemical structures.

2. Predict molecular interactions, including the target proteins' binding affinities.

3. Calculate the absorption, distribution, metabolism, and excretion (ADME) of pharmacokinetics.

4. Anticipate toxicological profiles well in advance of live testing.

By serving as a filter, these simulations reduce enormous compound libraries to a small number of promising candidates. Structure-based drug design, which simulates the interactions of particular chemicals with three-dimensional protein structures, is one of the most revolutionary techniques in this field. Other techniques that create better-informed pipelines include molecular docking, machine learning classifiers, and quantitative structure-activity relationship (QSAR) modeling.

Notably, in silico design

precision has increased thanks to platforms like AlphaFold and Pro3D, which can

now predict protein structures with startling accuracy. The final outcome? Bioinformaticians have the authority to

decide which chemicals should be developed further and which should be

abandoned based on evidence.

Experimental Validation: From

Code to Culture

Once a compound passes the digital inspection, it enters the wet lab. Here, a variety of biological tests are conducted by experimental scientists to evaluate the compound's practicality. These assessments are intended to ascertain:

1. How effectively the substance suppresses or stimulates its biological target.

2. Its effectiveness in animal models, tissue cultures, and cell lines.

3. Adverse responses, toxicological effects, and off-target outcomes.

However, this stage goes beyond simple confirmation. It is also diagnostic, revealing subtleties that the simulations could have overlooked. For instance, a substance may bind effectively in silico but not penetrate cell membranes in vitro. Alternatively, the emergence of unanticipated metabolites in biological systems could complicate the treatment profile.

The important thing is that this

lab data is not isolated. It returns to the digital realm, where it trains

machine learning algorithms, improves computational models, and adjusts

parameters for the subsequent prediction cycle. One of the main advantages of contemporary drug discovery is the

learning system this produces, where each cycle gets better than the one before

it.

Pharmaceutical Engineering:

Scaling the Science

Successful candidates now enter the realm of formulation science and pharmaceutical manufacturing. The aim is to convert encouraging laboratory findings into a pharmaceutical product that is both scalable and shelf-stable. Variables taken into account by formulation engineers include:

1. Pharmacological stability and solubility of the active component.

2. Selection of excipients and delivery systems (e.g., sustained-release capsules, injectables, and tablets).

3. The best possible dosage and bioavailability to optimize the therapeutic outcome.

4. Adherence to regulations for uniformity, safety, and effectiveness.

Modeling is also helpful at this stage. Simulations can forecast the potential effects of formulation modifications on performance. AI is used in advanced manufacturing to streamline production processes, lower waste, increase yield, and guarantee batch consistency.

Within the feedback loop, manufacturing

data enters the lab and computational realms in reverse. If a compound proves

difficult or challenging to scale, it may require reformulation. Moreover, if

degradation occurs during production, it may be necessary to update stability

models. The entire development chain is strengthened by this iterative loop.

Triangular Feedback Loop: A Model

of Interdependence

These three domains don’t operate in silos. Data flows in all directions as they form a triangle. Every triangle corner benefits and enlightens the others:

1. Drug discovery is started with accuracy and foresight thanks to digital modeling.

2. The predictions are verified and improved by wet lab testing.

3. Pharmaceutical engineering provides ideas for optimization and converts findings into treatments.

This cyclical interplay creates a

responsive ecosystem, where each drug's success, and failure, benefits the one

before it. It expedites schedules, lowers expenses, and—above all—provides

patients with more individualized and efficient care.